Ratchet straps are used by professional truck drivers, movers, and cargo shippers to securing their loads. The belts are made of heavy-duty material with a high strength breaking force and load capacity rating.

They also come with end fitting hardware which works with many anchor points. You can select from a range of colors, lengths, and ratchets, to design the perfect strap to meet your needs for hauling.

Cargo tie down straps

Straps for cargo tie-downs are crucial to keep your cargo secure and safe when you’re carrying large equipment, moving an automobile or shipping equipment. The user-friendly ratcheting mechanisms allow you to tighten the straps incrementally to ensure that your cargo is secure throughout transport.

The load rating of the working load is the most important consideration when deciding on a tie-down strap. This is the amount of weight the strap can support without breaking or falling apart. Consider the size of the item and the method by which it will be transported. It is best to use two straps to secure your load in the event of driving over rough terrain and carry a large load.

Another aspect to bear in mind when selecting a tie down strap is the length and width. A strap that is longer will offer more coverage and provide a greater scope of support, whereas a narrower strap is easier to wrap around lighter loads. In addition, if you’re using the straps to secure various objects together It is recommended to use two of the same ratchet straps instead of than one ratchet strap. This will stop one strap being stretched too far and damaging the object you are trying to secure.

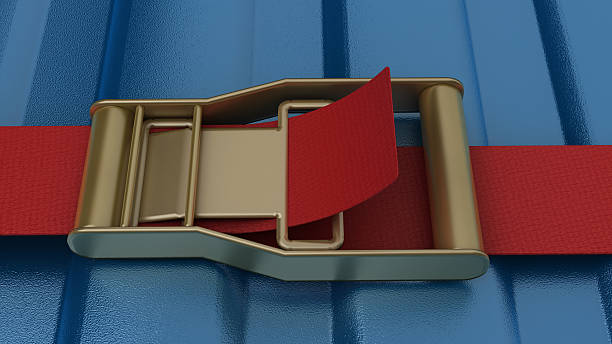

Ratchet Strap Mechanism

Ratchet straps come with an innovative ratcheting mechanism that allows for fast and stable tensioning of cargo, ensuring it is secure during transport. They’re also user-friendly and adjustable to fit a variety of sizes and shapes. This helps to ensure that cargo is safely fastened and won’t move during transport which makes them an ideal tool for truckers as well as other professionals looking to secure their cargo quickly and effectively.

It’s important to check for indications of wear prior to using the Ratchet belt. In particular, if the strap has been exposed to heat, such as exposure to direct sunlight or near engines, the webbing made of polyester may weaken over time. In such cases it’s recommended to keep the strap in a cool and dry place to prevent any future harm.

If you’re ready for using the ratchet strap, start by opening it fully and laying it flat. Grab the strap at the non-fixed part that is typically on the opposite side to the ratchet. Then pull it until it becomes loose. Then, feed the strap through the ratchet, and make sure you tighten it until there is enough free space. It is then possible to connect any fittings to the end you’ll need, including chains anchors, flat hooks, grab-hooks, or D-rings.

Straps for Heavy-Duty Tie Downs

Straps that have high break strength ratings to secure heavy machinery, vehicles, or other cargo on the back of flatbed trucks, large trailers or any commercial vehicle for cargo. These straps are constructed of reinforced webbing with a higher break strength rating than standard tie-down straps made of polyester and feature hardware made for long-lasting use. These straps also have a mechanism that prevents the straps from being too tight and damaging your cargo.

Professional movers love the efficiency of cam buckle belts with ratchets. The hardware for the cam buckle flows in one direction, which ensures that the webbing can be adjusted to the level of security. This reduces the chance of damage to your clients’ belongings that may be irreparable.

The straps are used to haul ATVs and UTVs and kayaks, motorbikes, boats and other light-weight items. These straps can be attached to anchor points like bent snap hooks, D rings, or axles of cars, trucks, and SUVs, or tools like E-track rails.

These ratchet straps are also made with weather-resistant polyester webbing which is resistant to elements outside like direct sunlight, UV rays rain, snow, hail or powerful winds. Webbing is able to be submerged for a short period of time in water without degrading.

Securing Cargo with Straps

The use of ratchet tie down straps properly ensures that the cargo is secured securely to avoid it shifting or falling during transportation. This decreases the possibility of accidents or incidents caused by loose cargo in an trailer or truck for example, injuries, environmental contamination or property destruction. This will ensure that the load is compliant with regulations applicable to large or heavy loads.

Choosing a ratchet strap with an appropriate break strength, length and fittings that are compatible with the end helps ensure that the straps be secured to your cargo safely and securely. Also, choosing the strap with a load limit for working visible on the webbing will help to ensure that you are not in excess of the safety limit of your transporting cargo.

Once you have selected an appropriate ratchet strap attaching your cargo to the strap is a tang do chang hang simple process. First, you must remove any loose material by pulling the loose end of the strap to tighten it. Attach the strap’s other end to the ratchet’s slot and then pull the strap up. Repeat this process until you achieve the tension you desire and a snug fit against your cargo. Once you’re done, be sure to examine the fit for secureness and test for any evidence of damage to your strap or cargo.

Taking the time to select and utilize a appropriate ratchet strap can save you from having to replace your equipment for securing cargo over time. Other suggestions to ensure your cargo is secured include using other restraint systems, adhering to the local and industry standards, and ensuring that employees are educated.